GIBSON NEWS

Gibson is pleased to announce an update to its liquidtight connector ferrule design in response to an industry shift, as galvanized core LFMC is now sharing the market alongside the growing demand for stainless steel core LFMC. This update ensures a seamless installation with all LFMC core types.

Gibson offers the liquidtight connectors in sizes ½” – 1” in the straight, 45° and 90° styles. Both standard and grounding versions are available, and all are 100% Made in USA. Gibson utilizes the higher grade of Type 316 SS for the entire fitting, including the inside ferrule, allowing for increased corrosion resistance.

These connectors complement Gibson’s flexible conduit line, offered in a standard and food grade versions.

The National Sanitation Foundation (NSF) sets rigorous standards to ensure the safety and sanitation of food equipment.

After extensive review, Gibson is proud to announce that its stainless steel conduit, couplings, and elbows are now NSF Certified, meeting strict requirements for sanitation, hygienic design, and food-grade applications. Additional product lines have also been reviewed, meeting the requirements for NSF certification and will be announced in the months ahead as Gibson works to incorporate NSF marking into the product.

As we transition our stock, some inventory may not reflect the NSF marking. Please contact the factory for specific details or needs.

The founding members of STI’s stainless steel committee, including Gibson Stainless, have been working with food & beverage industry associations to promote the benefits of stainless steel in corrosive, wash-down applications. While specifications around electrical systems in food areas are still developing, the FDA has acknowledged stainless steel as a material that is safe in food areas.

Please click here to learn more about Gibson’s recent food & beverage product line enhancements.

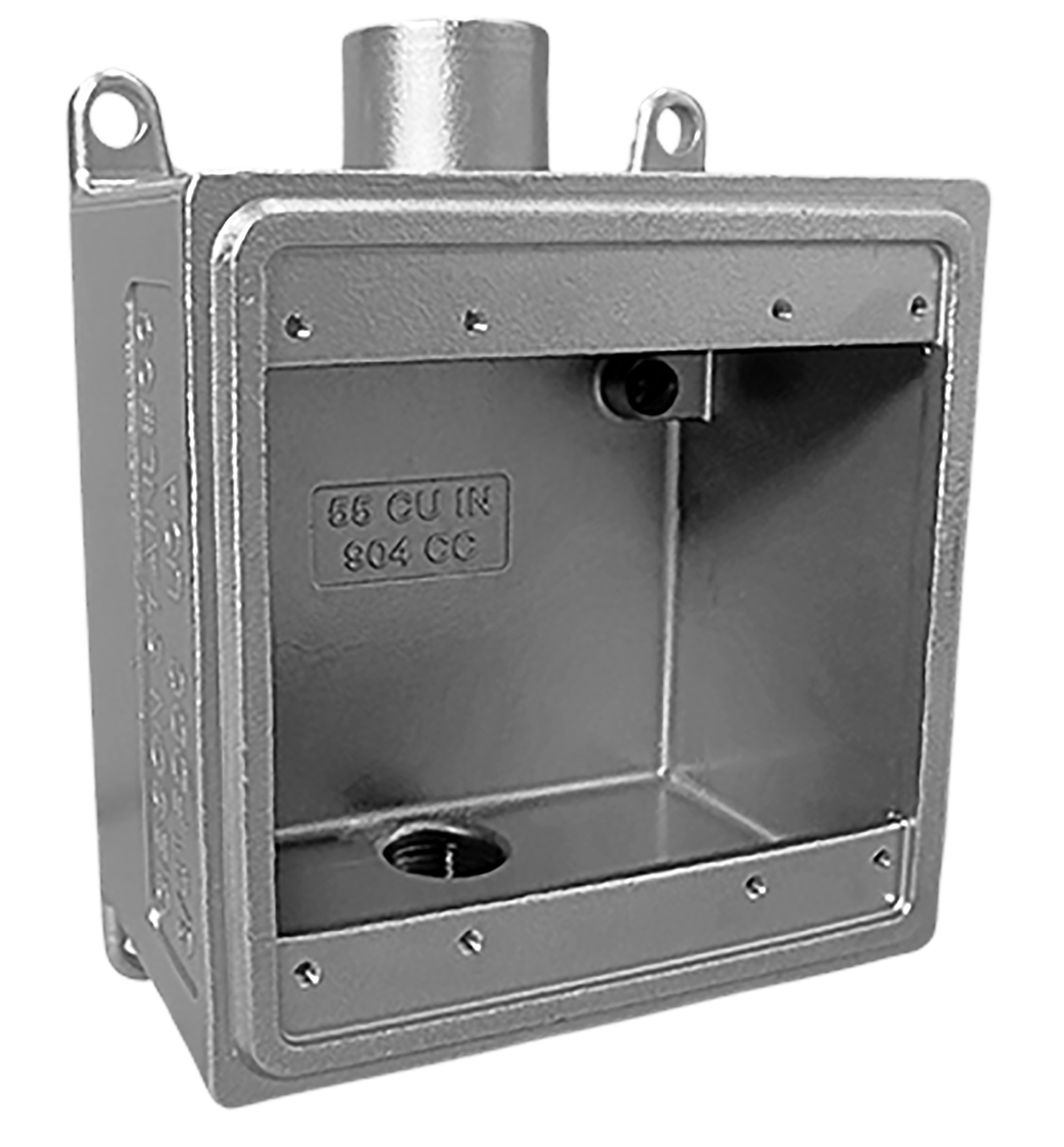

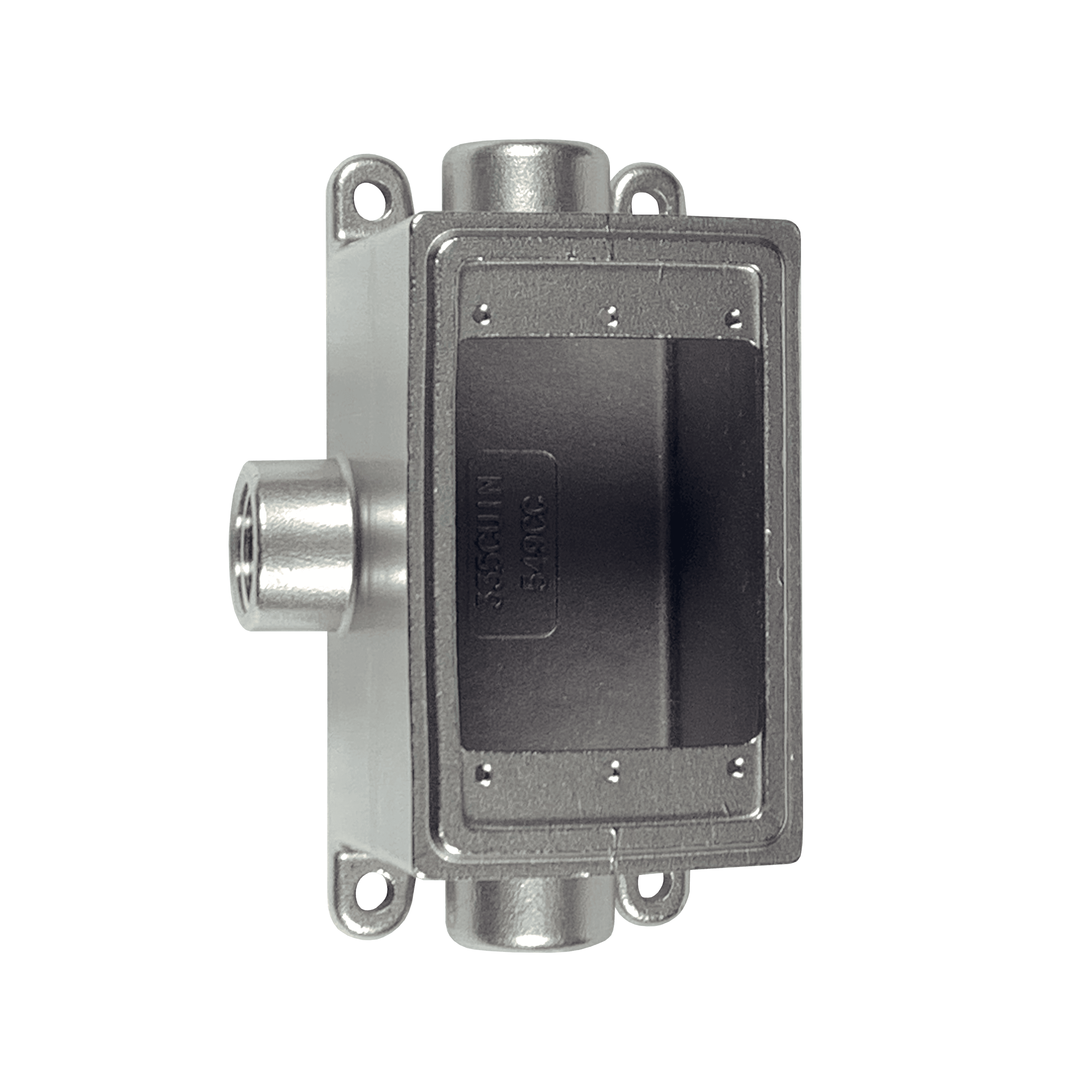

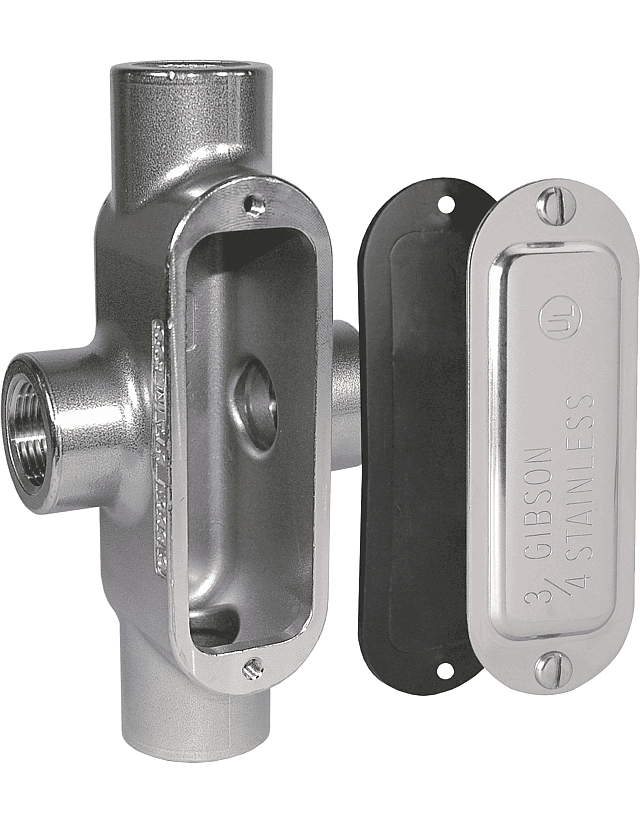

Gibson Stainless has added the 3/4″ Single-Gang FDCC Device Box to its product line.

Device Boxes are used to wire devices such as switches and receptacles, act as pull boxes, and connect conduit. The FDCC75 features three hubs, two on the top of the box and one on the bottom.

Gibson is now represented by Bray Sales Company in Iowa and Nebraska!

Since 1968, Bray Sales Company has been a trusted partner in the electrical industry – providing expert guidance, dependable support, and prompt service to help electrical professionals deliver seamless, successful projects.

For more information, please visit braysalesco.com.

Celebrating 30 years of innovation and customer-focused solutions, Gibson Stainless & Specialty, Inc. is pleased to announce key enhancements to its product line for the food and beverage industry. These updates reflect the company’s dedication to listening to customer feedback and adapting to the evolving demands of this growing market.

Gibson Stainless is excited to announce that it is now represented by Convergence in Kansas and Western Missouri.

Convergence has specialized in supplying electrical products for over 30 years.

For more information, please visit convergerep.com.

Gibson Stainless has added the While-In-Use Cover to its product line.

While-in-use covers are designed to be used with Gibson single-gang device boxes in a vertical orientation to protect switches and receptacles against outdoor elements such as rain and snow or the spraying of water and use of cleaning chemicals often found in washdown environments.

Gibson’s heavy-duty, deep design allows the cover to be fully closed while cords are plugged in and includes a notched closure tab to ensure the cover remains closed. A sloping design helps prevent the pooling of water and a padlock feature ensures electrical safety and security. The covers meet the latest NEC requirements for wet locations and extra duty applications.

Please click here for more details.

Gibson Stainless has expanded its Device Box Cover product line to include the Ground Fault Circuit Interrupter, GFCI.

The GFCI Cover offers corrosion-resistant protection for a GFCI receptacle in a single-gang device box.

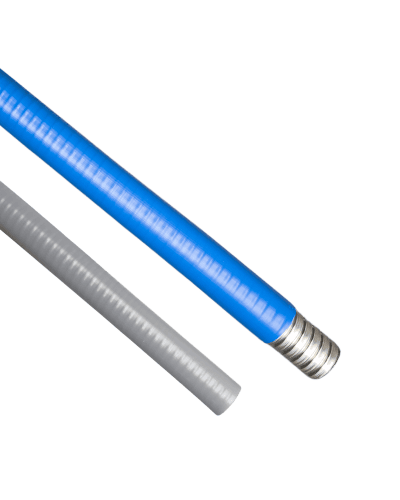

PVC-Jacketed SS LFMC and Food-Grade PVC-Jacketed SS LFMC

We are excited to announce that we have added PVC-Jacketed SS LFMC and Antimicrobial, Food-Grade PVC-Jacketed SS LFMC, to our product line!

Liquidtight flexible conduit provides a flexible and liquidtight means of protecting wiring and cable when making connections to rigid electrical systems.

These products will be offered at any length in sizes ½ in., ¾ in., and 1 in.

Please click here for more details.

Gibson Stainless has added the 3/4″ Double-Gang FDDC Device Box to its product line.

Device Boxes are used to wire devices such as switches and receptacles, act as pull boxes, and connect conduit. The FDDC75 features two hubs, one on the top of the box and one on the bottom for a “feed-thru.” The bottom hub may be plugged if a “dead-end” entry is needed.

Please click here for more details.

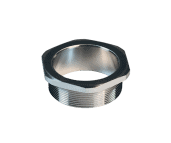

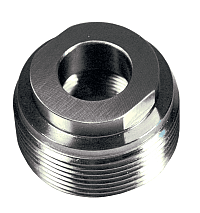

Gibson Stainless has expanded the Face Reducing Bushing product line.

Face Reducing Bushings provide a means of connecting a smaller size of conduit to a larger conduit fitting port.

The following sizes have been added: 2-½ x 1, 2-½ x 1-½, 2-½ x 2, 3 x 1, 3 x 1-½, 3 x 2, 3 x 2-½, 4 x 2, 4 x 2-½, and 4 x 3.

Please click here for more details.

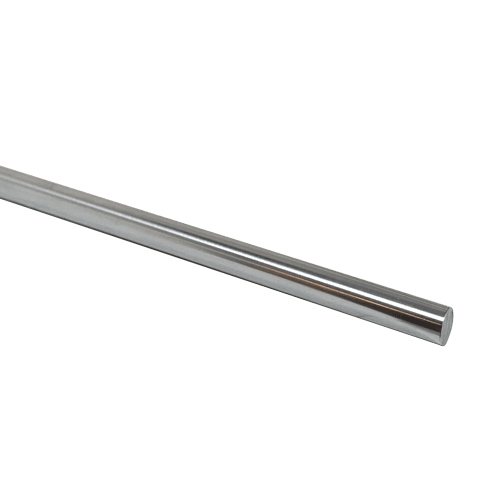

Gibson Stainless has added unthreaded rod, also known as slick rod or hanger rod, to its product line.

Unthreaded rod can be threaded in the field to fit specific applications and provides a means of hanging or suspending conduit systems, piping, strut, etc.

This product is offered in 316SS in sizes ¼ in. x 10 ft, 3/8 in. x 10ft, ½ in. x 10 ft.

Please click here for more details.

Gibson Stainless has expanded the FDC product line to include the 1″ size.

Device boxes are used to wire devices such as switches and receptacles, act as pull boxes, and connect conduit. The FDC features two hubs, one on the top of the box and one on the bottom for a “feed-thru.” The bottom hub may be plugged if a “dead-end” entry is needed.

Please click here for more details.

Gibson Stainless has expanded its conduit nipple to include the 2-1/2″, 3″, and 4″ sizes.

Stainless steel conduit nipples are used to extend conduit systems and can be connected to boxes, enclosures, other lengths of conduit, etc. Nipples are threaded at both ends, NPT.

Please click here for more details.

Gibson Stainless has expanded its three-piece coupling line to include the 2-1/2″, 3″, and 4″ sizes.

Three-piece couplings are used to join and connect the threaded ends of rigid conduit where the conduit cannot be turned.

Please click here for more details.

Associated Representatives will now represent Gibson Stainless in Utah, southern Idaho, western Wyoming, and eastern Nevada.

For over 35 years, Associated Representatives has serviced its market, specializing in commercial construction, industrial construction and maintenance, OEM, and utility construction and maintenance.

For more informations, please visit associatedreps.com.

Gibson Stainless has added drain plugs to its product line.

Drains are used to release water from electrical conduit systems and to act as breathers to reduce condensation.

This product is offered in sizes 1/2″ – 1″ in Type 316 SS. The plugs are 100% Made in USA; the sintered metal filter is German.

Please click here for more details.

Gibson Stainless is excited to announce it will be represented by Gormley-Farrington in Western Pennsylvania and West Virginia.

Gormley-Farrington has proudly served both the lighting and electrical industries in Western Pennsylvania and West Virginia for over five decades. Founded in 1970 and family owned, Gormley-Farrington has built a reputation on customer service and a commitment to providing a solution within the best interest of the customer.

For more information, please visit gormley-farrington.com.

Centauri Martin will now represent Gibson Stainless in New Mexico (except for Lea county) and the El Paso market. Founded in 1988, Centauri Sales became a leading electrical manufacturer’s representative agency. In 2020, Centauri Sales joined with JD Martin. Centauri Martin is “proud and privileged to have become trusted, long-term partners to their local customers and manufacturers alike, ensuring a long and fruitful relationship to both.”

For more information, please visit centaurisales.com.

Gibson Stainless has added chase nipples, also known as box connectors, to its product line.

Chase nipples are used with a coupling to connect conduit to a box or enclosure or to connect two boxes side by side or back to back with a locknut.

The chase nipples are offered in sizes 1/2″ – 4″ in Type 316 SS and are 100% Made in USA.

Please click here for more details.

Gibson Stainless & Specialty is pleased to welcome Locust Electric Sales to the team. Locust Electric will represent Gibson in eastern Pennsylvania, southern New Jersey, and Delaware.

Locust is focused on “strong alignments with the top distributors and direct contact with contractors, municipal planners, and the specifying engineering community.”

For more information, please visit locustelectric.com.

Electrical Sales Associates will now cover all of Virginia, Maryland and Washington DC for Gibson.

Gibson Stainless is pleased to announce that John Moore & Associates will cover eastern Tennessee. In business since 1972, John Moore & Associates has over 300 years experience between their inside and outside sales teams.

For more information, please visit jmaone.com.

The C. C. Pierce Company will now represent Gibson Stainless in upstate New York.

C.C. Pierce has served the electrical market for over 98 years, utilizing its extensive industry knowledge and market awareness to serve its customers.

For more information, please visit ccpiercecompany.com.

Gibson Stainless will now be represented by the MRL Company in the following territories: North Dakota, Eastern South Dakota, Minnesota, and Western Wisconsin.

MRL’s focus as a company is “to represent and market quality manufacturers and to operate profitably and ethically to the benefit all of our customers, manufacturers, and employees.”

For more information please visit mrlcompany.com.

Gibson Stainless has added the FDCT configuration to its device box product line.

Device boxes are used to wire devices such as switches and receptacles, act as pull boxes, and connect conduit. Gibson Stainless currently offers the deep-style device boxes with 3/4″ NPT threaded hubs. These device boxes are often used with Gibson Stainless device box covers which are offered in three styles: blank, receptacle, and switch.

These fittings are cast CF8M (316 SS) and they are 100% Made in USA. Please click here for more details.

As part of our planning and response to COVID-19, we want to provide an update on what you can expect from Gibson Stainless & Specialty, Inc.

First and foremost, the health and safety of our employees, as well as the community, is our top priority. We are committed to taking the necessary steps to provide a safe working environment.

Our business is proceeding; we are manufacturing and shipping orders without interruption. At this time, we have not been made aware of any supply chain issues that could impact our level of service. We will continue to monitor this and work to mitigate any delays that may arise.

Gibson Stainless will continue to monitor the COVID-19 situation as well as guidelines from the CDC and WHO. We will provide updates regarding any changes to our current business process and capabilities.

We wish everyone health and safety during this difficult time and thank you for your continued support.

Lake Michigan Sales will now represent Gibson Stainless in the following territories: northern Illinois, eastern Wisconsin, upper Michigan, and northwest Indiana. “Lake Michigan Sales is dedicated to continuous improvement through training, technology, planning, and marketing. We maximize our results using excellent communication with our manufacturers, distributors, and decision makers.”

For more information please visit lakemichigansales.com.

Gibson Stainless has added the 45° elbow to its product line.

Stainless steel conduit elbows are bent sections of rigid conduit to help in changing the direction of conduit. Gibson Stainless offers standard radius, 45º elbows in Type 316 SS and Type 304 SS. Elbows are threaded on both ends with NPT threads and are supplied with two thread protectors.

Gibson Stainless has added insulated bushings and grounding bushings to its product line.

Stainless steel insulated bushings are designed for use with threaded conduit to terminate runs and to provide a smooth surface for wire pulls.

The grounding bushings are provided with a Type 316 SS grounding lug and screw to ensure a secure connection for ground wiring. Gibson stainless offers the lugs in Type 316 SS in two sizes. The smaller lug is designed for wire ranges 4-14 AWG. The larger lug is designed for wire ranges 3/0-6 AWG.

These fittings are manufactured entirely in Type 316 SS and they are 100% Made in USA. Please click here for more details.

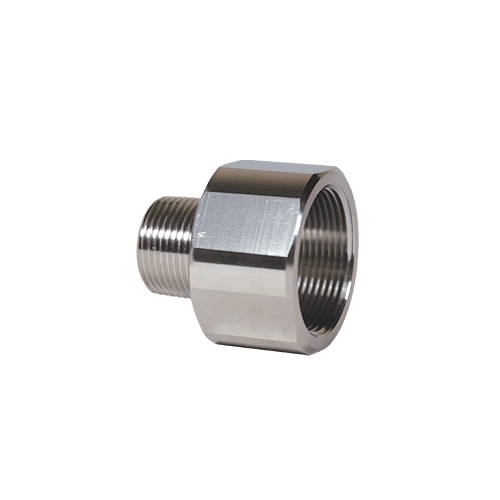

Gibson Stainless has added a new product to its product line: stainless steel enlarger bushings.

Enlarger bushings are designed to convert a smaller female port to a larger conduit size. These fittings are threaded male to female with NPT threads.

Gibson Stainless manufactures these fittings entirely in Type 316 SS and they are 100% Made in USA. Please click here for more details.

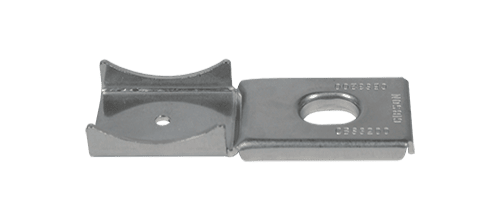

Gibson Stainless has redesigned its clamp back spacer product line.

Clamp back spacers are designed for use with rigid conduit and one hole straps to provide space between the conduit and the surface on which it is mounted.

Gibson Stainless manufactures these fittings entirely in Type 316 SS and they are 100% Made in USA. Please click here for more details.

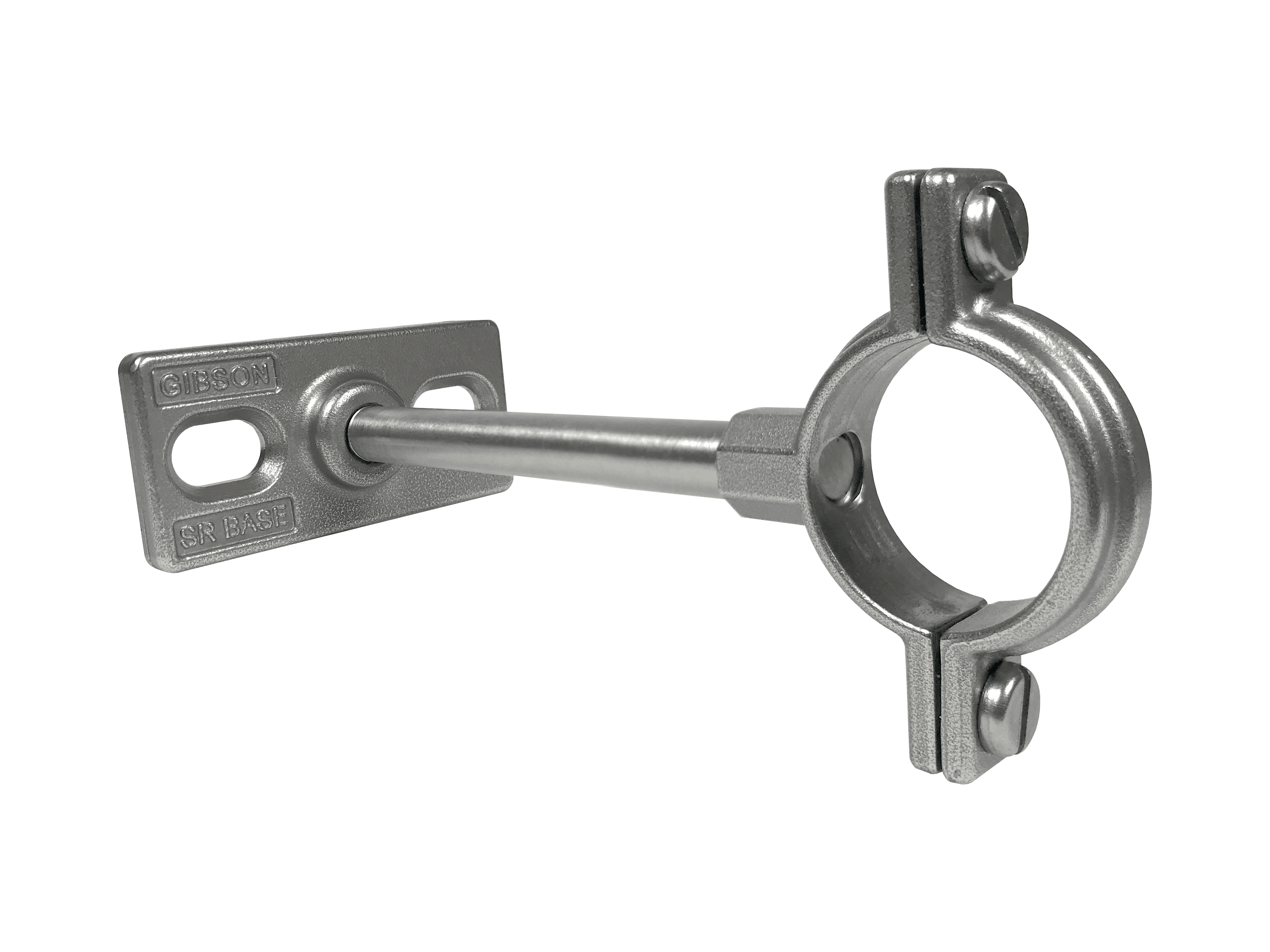

Split ring clamps are designed to provide space between a raceway and the wall, floor, ceiling or other structure on which it is run. This “stand-off” is often found in wash-down areas where water and chemicals are used and where it is necessary to ensure nothing is trapped between the conduit system and the mounting surface. Gibson split ring clamps can be used for vertical or horizontal conduit runs.

Gibson Stainless sells the split ring clamp components separately; all components are 100% Made in USA.

More information can be found here.

Gibson Stainless will now be represented by West Pacific Power Products, Inc. in Hawaii.

West Pacific Power Products, Inc. was established in 1994 and has over 20 years of experience providing customer service to the electrical industry. Its team has long standing relationships with electrical consultant, distributor, contractor, end user, and principal partners.

West Pacific Power Products, Inc.

3049 Ualena Street

Suite 902,

Honolulu, HI 96819

(808) 522-0511

Fax (808) 522-0513

Website: www.westpacificpowerproducts.com

Gibson Stainless has added floor flanges to its product line.

Floor flanges are designed to mount threaded conduit to floors or walls and are used predominantly where the conduit is being used as a structural member. The floor flanges are offered in sizes ½” – 2” in Type 316 SS and are 100% Made in USA.

More information can be found here.

Gibson Stainless & Specialty, Inc. has expanded the C, LL, and LR conduit body product lines to include the 1-½” and 2” sizes.

Heavy-duty, cast CF8M (316 SS) stainless steel conduit bodies are designed to make 90º bends, to change the route of conduit, and/or to make wiring pulls and connections. These Form 8 conduit bodies permit simple, easy, installation using ordinary hand tools. A flat back design provides extra wiring capacity.

Each conduit body is supplied complete with a cover, gasket and screws. These conduit bodies are UL Listed and are 100% Made in USA.

In an effort to enhance, consolidate, and streamline sales efforts in Canada, Gibson Stainless has entered into an agreement with Summit Electric Products for exclusive sales rights in all Canadian provinces.

Summit has been representing Gibson Stainless in Ontario for several years and has enjoyed great success and growth. Summit stocks Gibson products including stainless steel conduit. Please contact them for all Canadian inquiries.

Summit Electric Products Limited

3333 Devon Drive

Windsor, Ontario N8X 4L5

Phone: 1.800.265.4822

Fax: 1.519.250.8389

Website: www.summit-electric.com

As always, Gibson will still be available for technical support if necessary.

Gibson Stainless is introducing conduit caps to its product line.

Conduit caps are used to end runs of conduit in a conduit system. These caps can allow for future system expansion or rerouting of conduit. Caps have NPT threads and are designed for use with rigid conduit. Hexagonal flats allow for easy tightening with standard hand tools.

The caps are offered in Type 316 SS in sizes ½” – 4” and are 100% Made in USA.

More information can be found here.

Gibson Stainless has added cord grip connectors to its product line. The connectors are offered in Type 316 SS in sizes ½” – 1” and with or without mesh.

Cord grip connectors are designed to provide a means of terminating flexible cord or cable in devices, boxes, or enclosures. Cord grip connectors provide a weather-tight seal and, when specified with a stainless steel mesh grip, prevent the transfer of tension from the cable to the terminals or joints contained within the device, box, or enclosure. In addition to pull-out protection, the strain relief mesh also helps to prevent over-bending and kinking of the cord.

More information can be found here.

Right Sales & Service will now represent Gibson Stainless in the north and central areas of Indiana.

Right Sales & Service was established in 2011 and has a team with over 100 years of combined experience in the electrical industry. Their team focuses on Indiana electrical markets for residential, commercial and industrial products along with some utility.

To learn more visit https://www.rgt4u.com/.

The A.L. Pickens Company, who has represented Gibson Stainless in Kentucky and parts of Indiana for 17 years, will now cover the southern Indiana counties of Posey, Gibson, Vanderburgh, Warrick, Pike, Spencer, Dubois, Perry, Crawford, Orange, Harrison, Washington, Floyd, Clark, Scott, and Jefferson.

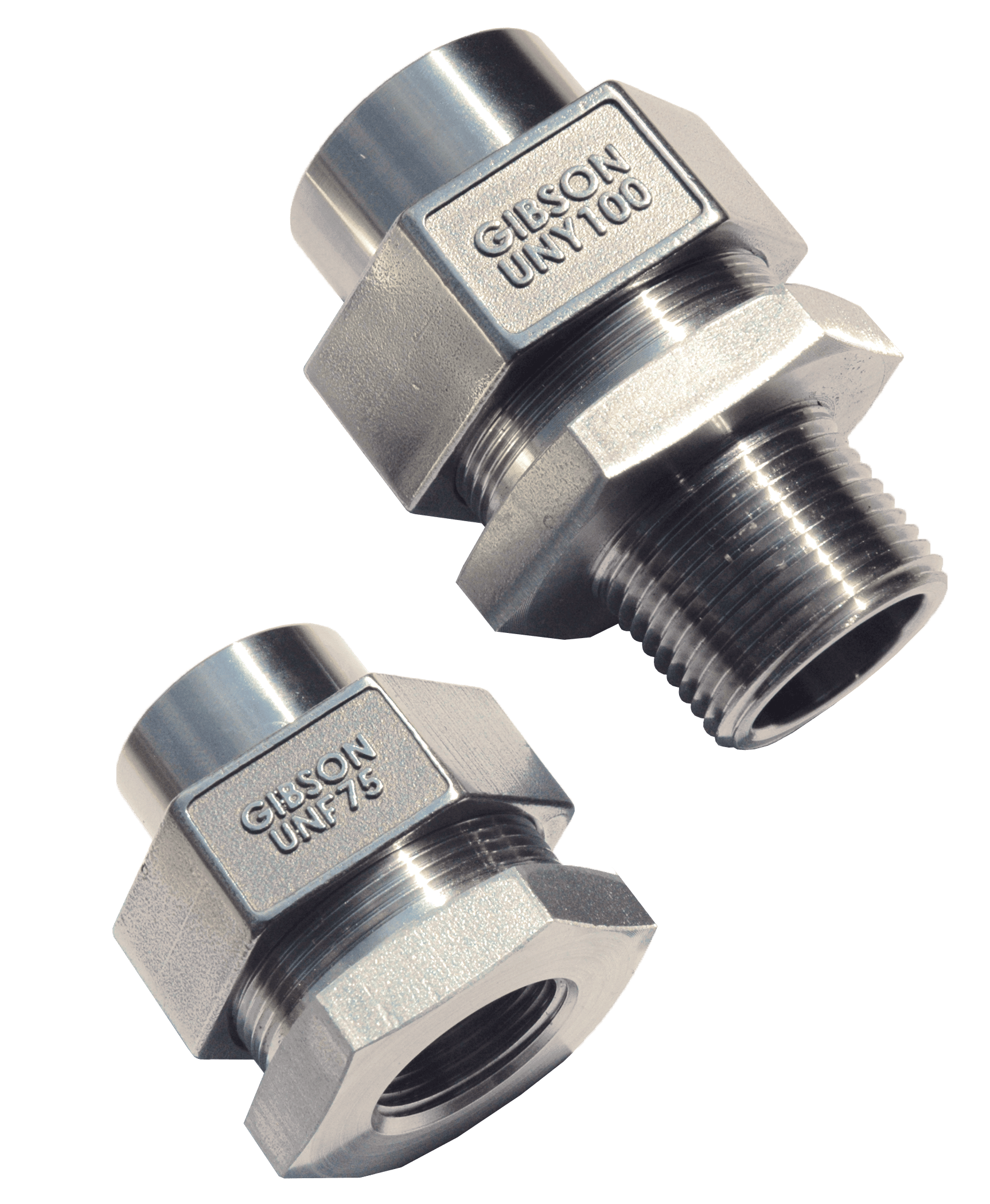

Gibson Stainless has added UNF and UNY fittings to the product line. UNF and UNY fittings, also known as explosion-proof unions, are designed for use in hazardous area locations to join threaded lengths of conduit or to connect rigid conduit to devices, boxes, or enclosures.

These fittings are Type 316 SS and manufactured in the USA. Sizes ½” – 1” are currently offered.

More information can be found here.

Gibson Stainless has added the “Drop In Anchor” to its product line. The drop in anchor is an internally (female) threaded anchor that can be used with standard hex head bolts.

Sizes 1/4”, 3/8” and 1/2” are currently offered.

More information on the drop in anchors can be found here.

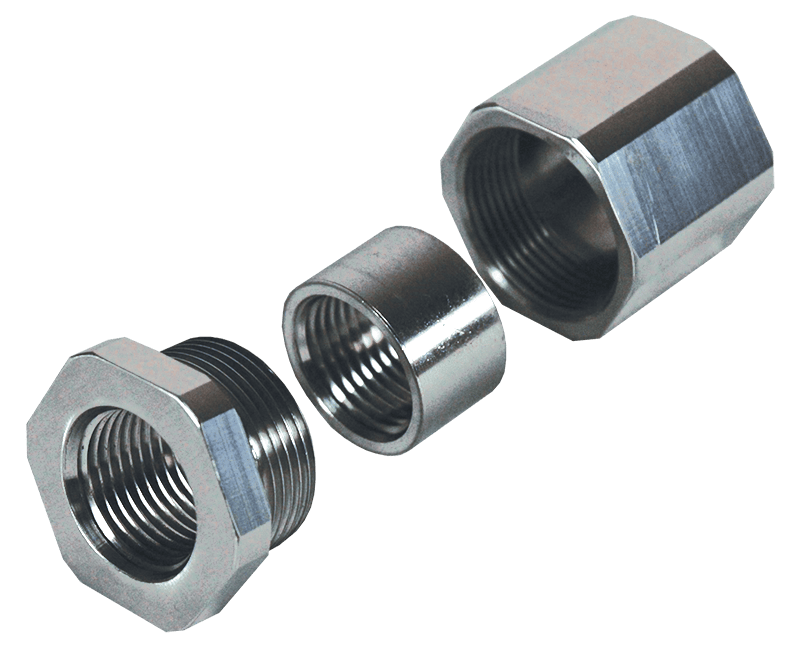

Gibson Stainless has redesigned and expanded its Three-Piece Coupling product line.

Three-piece couplings are used to join and connect the threaded ends of rigid conduit where the conduit cannot be turned. Using three-piece couplings allows for future modifications to the conduit system without full disassembly.

Gibson Stainless manufactures these fittings entirely in Type 316 SS. Sizes 1/2″ – 2″ are now offered. Please click here for more details.

Gibson Stainless & Specialty, Inc. is introducing Pulling Elbows to its product line.

Pulling elbows are designed for use with rigid conduit to make wiring pulls at 90° bends in a conduit system. Pulling elbows can aid in instances of sharp bends and allow a straight pull in either direction.

Each pulling elbow is supplied complete with Type 316 SS cover, neoprene gasket, and Type 316 SS screws.

Gibson Stainless manufactures the pulling elbows in CF8M (316 SS) and they are 100% Made in USA. Please click here for more details.

Gibson Stainless & Specialty, Inc. has added a new style of reducing bushing to its product line: the face reducing bushing. Similar to the hex head reducing bushing, the face reducing bushing provides a means of reducing the size of a female threaded port while eliminating the hex head component, creating a cleaner, more seamless appearance. An integral wrench boss facilitates installation of the bushing onto the smaller raceway while a smooth throat helps protect conductors during wire pulling.

These fittings are all 100% Made in USA. Various sizes are in stock and available now. Please click here for more details.

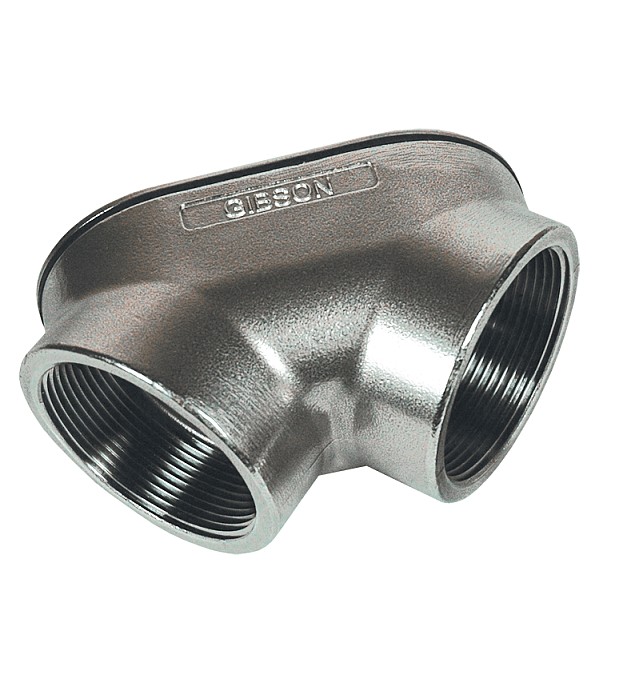

Gibson Stainless is introducing a new configuration to its conduit body product line. The “X” conduit body has now been added to the line that contains the C, LB, LL, LR, T, and TB styles. The “X” is currently available in the 3/4” and 1” sizes, which are in stock and available for immediate shipment.

Conduit bodies are designed to make 90° bends, to change the route of conduit, and/or to make wiring pulls and connections. These Form 8 conduit bodies permit simple, easy installation using ordinary hand tools. A flat design provides extra wiring capacity. Each conduit body is supplied complete with a cover, gasket and Type 316 SS screws. All Gibson Stainless conduit bodies are 100% Made in USA.

Gibson Stainless & Specialty, Inc., a leading manufacturer of stainless steel conduit and fittings has completed its move to a new larger facility. The new building was designed and built for Gibson Stainless, containing 25,000 square feet of manufacturing space as well as 5,000 square feet of office space.

The facility also contains new state of the art equipment and machinery to accommodate the growth of the company. With the additional space Gibson will continue to increase inventory levels and develop new product lines.

In the upcoming months new products, policies, and procedures will be announced. Please stay tuned to gibsonstainless.com.